It's Our Mindful Management that Sets Us Apart

Sort

By classifying and separating each production material, we reduce the chance of material contamination by 99%.

Set in Order

The production equipment and parts is positioned accurately and precisely to save organizing time and boost output.

Shine

We keep track of the daily hygiene maintenance within factory and carry out frequent audits and reports.

Standardize

In order to provide quality consistency and standardization, all manufacturing processes are guided and regulated.

Sustain

Conduct regular training sessions to develop positive work habits and proactive 6S management participation of the staff.

Safety

Overseeing the whole production process, ensuring safety precautions by anticipating and mapping out risk locations.

Every Equipment is A Chance to Thrive

For NEWTOP, Quality Checks Isn’t Just a Checklist

Pre-Verified Component Supplier

Our commitment to component reliability is certainly the key to our numerous long-lasting relationships, as NEWTOP consistently delivers premier equipment by partnering with the same suppliers of the world’s leading brands for more than 20 years.

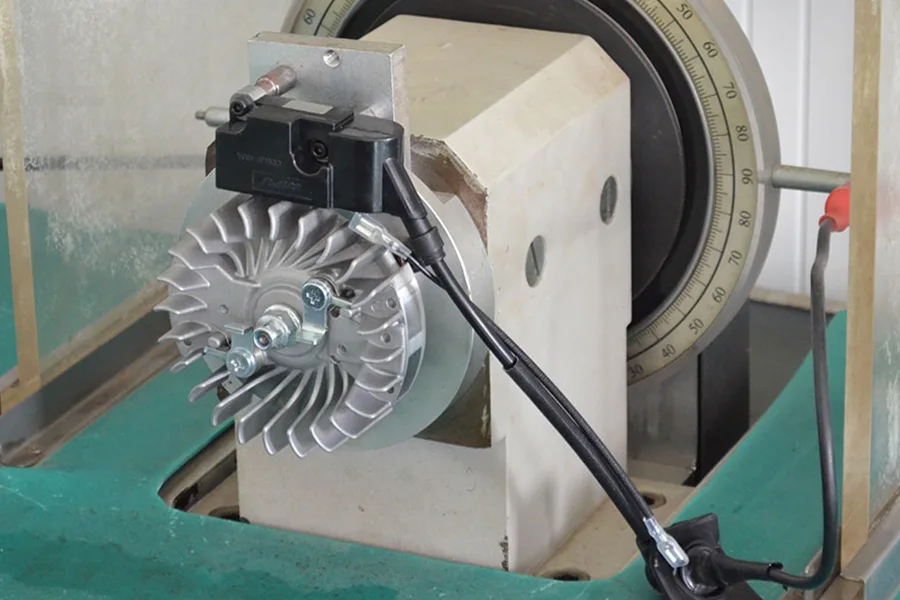

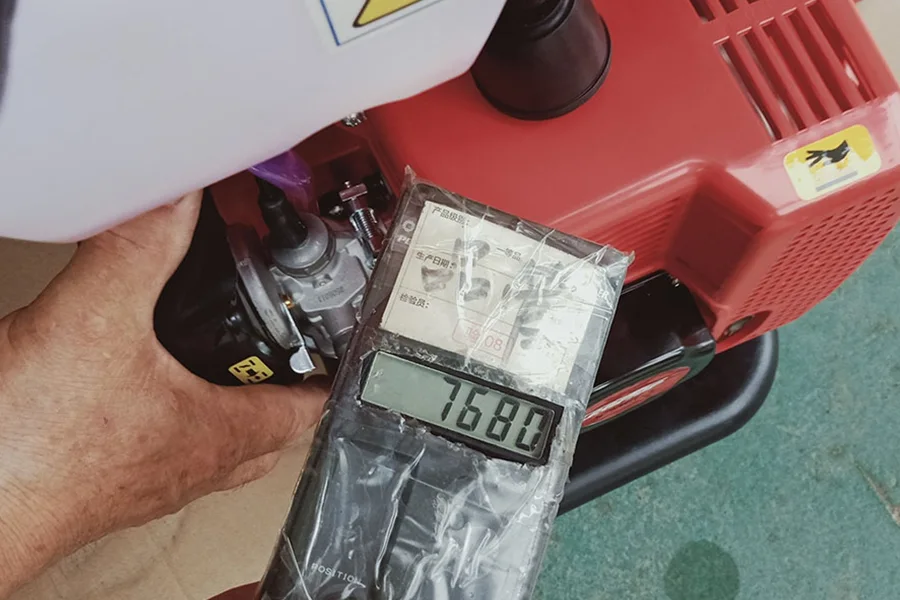

Component Testing Processes

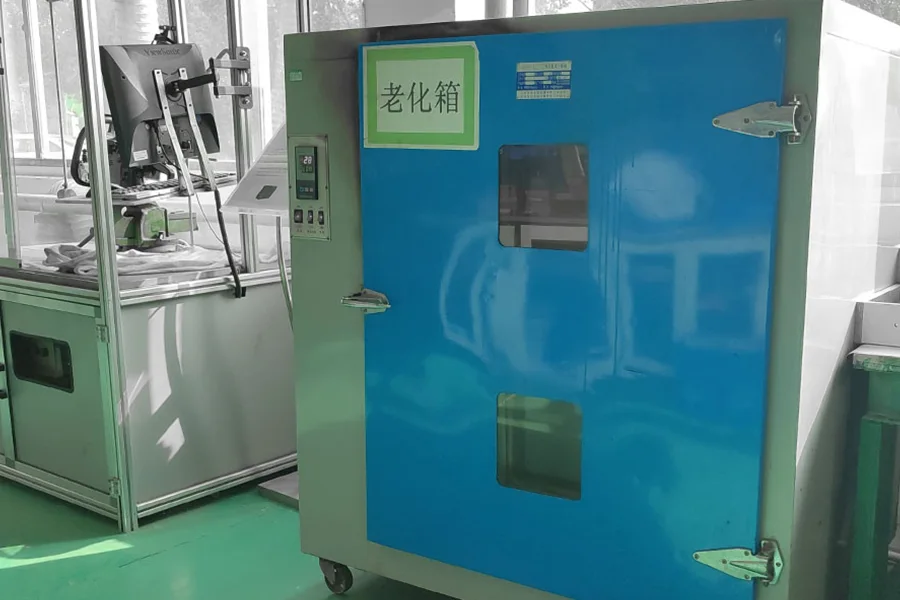

Internal Testing Laboratory

Patrol Inspection

Assembly Inspection

Packaging Inspection

Multi-purpose Final Product Inspection

Mechanical Strength Test

Aging Test

Powers Test

Salt Spray Test

Hardness Test

Our Honorable Partners

Learn More From NEWTOP